Manufacturing analytics for enterprises

Reduce supply chain disruptions, improve production quality and safety, and boost profitability with better insights into the manufacturing process.

KNIME powers solutions for manufacturers across the globe

Forecast demand and optimize inventory with clear insights into changing customer behavior.

Improve processes and product quality, and reduce costs by automating monitoring, tracking, and reporting.

Supercharge product R&D with a feedback loop driven by customer and operational insights.

Success stories

Use Cases

My very first use case using KNIME, the time reduction we achieved was over 90%. Before, we used three hours for reporting, repetitive Excel tasks. Afterwards it took only ten minutes.

Phillipp Kowalski, Digital Enablement Agent, Siemens

Why KNIME for manufacturing

Data preparation to ML modeling in one intuitive platform

- Enable scientists to build analytic models and automate tedious spreadsheet work with an easy-to-use, visual programming interface - no coding needed. Speed up insights with a genAI assistant to auto-create analysis as well as provide guidance.

- Lower the barrier to data science with low-code/no-code, and provide access to novel and highly advanced algorithms including LLMs that can be applied on big datasets.

- Give teams the flexibility to script custom algorithms in their preferred language with built-in integrations with R, Python, Java, and more and the choice to auto-generate scripts with genAI.

Power DMAIC with sophisticated analytics

- Combine the Six Sigma approach with advanced analytics techniques and eliminate tedious spreadsheet work for more accurate recommendations on process improvement.

- Automate data collection and analysis without any restrictions on size or format, make correlations, enhance error recognition, and gain insights to set up process improvement solutions.

Enterprise-scale data analytics platform

- Give teams all the data access they need while ensuring enterprise needs of data privacy and security are met.

- Deliver sophisticated machine learning models as data apps to business users to ensure data-driven decision-making across the entire organization.

- Share and reuse analyses and deploy them wherever you want, whether that’s on-premises or in the cloud.

Future-proof with open source

- Make the most of KNIME’s open-source approach to fuel future growth, and stay ahead with the constant advancements and innovation powered by a global, open-source community.

- Get thousands of ready-made solutions and blueprints for predictive maintenance, anomaly detection, inventory forecasting, and more in the KNIME Community Hub.

Using KNIME to produce total market data for client and datacenter at AMD

Business plans, targets, and GTM strategies all depend on AMD’s Total Available Market (TAM) forecasts. It’s critical to get it right but it involves processing millions of rows of data from multiple sources. See how a data team of just seven people have built a fully automated and standardized process framework for TAMs that serves the entire organization with reliable insight.

Improving Supply Chain Management at Audi with KNIME

Audi’s data analytics team leveraged KNIME to automate supply chain forecasting, using machine learning and simulation to optimize warehouse stock levels, reduce manual work, and improve decision-making—ultimately saving the company €30,000 per year while increasing efficiency, transparency, and debugging speed.

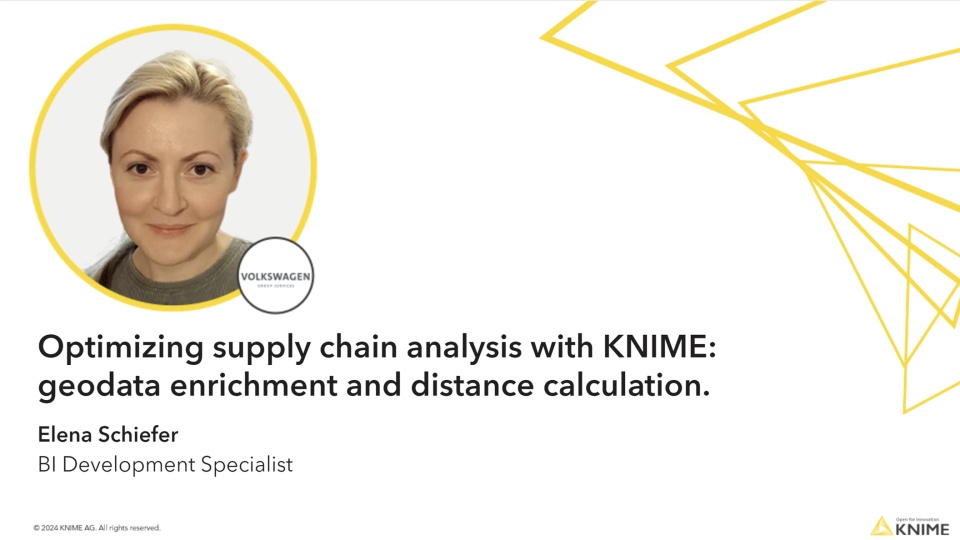

Optimizing supply chain analysis with KNIME: Geodata enrichment and distance calculation

Elena Schiefer from Volkswagen Group Services shared how her team used KNIME to enrich supplier data with regional information, leveraging an existing GeoServer to optimize procurement analysis—ultimately saving 500+ hours of manual work, improving data quality, and enhancing decision-making across the Volkswagen Group.