How Qualcomm Automated 35+ Smart Factory Processes in One Year with KNIME

See how Qualcomm launched 35+ smart factory use cases in a year using KNIME Business Hub — boosting capacity, speeding product launches, and empowering engineers with automation.

35+ smart factory use casesbuilt in just one year using KNIME

KNIME handles a high volume of critical production tasks

Domain experts now lead automation processes

Summary

The challenge:

- Swiftly adapting to rapid environmental changes and needs.

- Empowering process engineers — most of whom aren’t programmers — to deploy automated, data-driven decisions.

- Ensuring any new solution integrated smoothly with existing Manufacturing Execution System (MES) and NiFi systems while scaling reliably.

The solution:

- Deployed KNIME Business Hub in a decentralized, high-availability setup across sites.

- Trained and certified 13 domain experts (KNIME “Power Users”) to build and manage workflows.

- Enabled business users to build KNIME workflows, collaborate on KNIME Business Hub and integrate their domain knowledge into data work.

- Connected KNIME to the manufacturing system and server landscape for event-based triggers.

The results:

- 35+ smart factory use cases rolled out in the first year, including dynamic lot routing and automatic process parameter updates.

- Faster new product launches by centering run-to-run parameters immediately after sample runs.

- KNIME handles a high volume of critical production tasks, with domain experts now leading automation processes

Challenges: Adapting to Dynamic Manufacturing Needs

Qualcomm’s Radio Frequency Front-End (RFFE) division faced pressure to adapt production lines swiftly. Process engineers needed to reroute lots or adjust parameters but lacked tools to operationalize their domain knowledge.

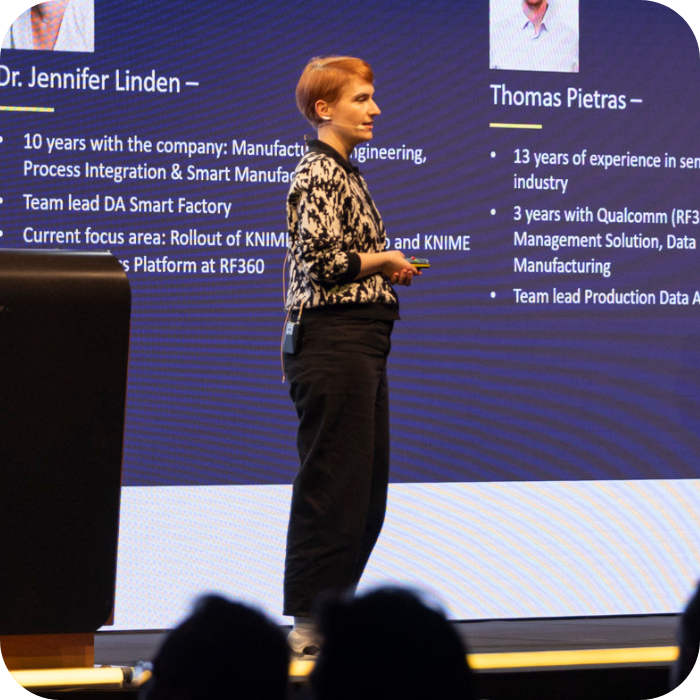

“On the one hand, we have our process engineers who bring the respective domain knowledge... but most of them are not really programmers.” Dr. Jennifer Linden, Team lead DA Smart Factory

Equally important was guaranteeing high availability and scalability. Qualcomm wanted a stable system that would balance scalability with integration into legacy systems like MES and Apache NiFi data flows.

“You're looking for high availability, resilience, and also scalability because if you only can deploy one use case, not so perfect. Right?” Thomas Pietras, Team Lead Production Data Analytics

Solution: KNIME Business Hub as a Smart Factory Enabler

To address these challenges, Qualcomm turned to KNIME Business Hub. They established a decentralized setup at manufacturing sites in Munich and Singapore. This multi-server strategy allowed each site to maintain local control while sharing common workflows.

Key Steps:

- MES Integration via NiFi: Apache NiFi listened for triggers in the MES, then called KNIME workflows via REST. Once KNIME processed the data, results were fed back instantly to the MES.

- Training Power Users: Qualcomm selected 13 engineers with deep manufacturing knowledge and trained them to become KNIME L3-certified, enabling them to build and deploy workflows independently.

- Scalable, Resilient Setup: By giving each location its own KNIME hub, Qualcomm ensured minimal downtime and easy expansion.

“When we want to choose a platform or a tool to support us, we need to consider some key factors. If we look from an IT perspective, you want to enable your colleagues but also support them with data analytics know-how. You’re looking for high availability, resilience, and also scalability.” Thomas Pietras, Team Lead Production Data Analytics

Use Case: Accelerating Run-to-Run (R2R) Setup

- Challenge: New products required time-consuming sample runs to calibrate R2R systems.

- Solution:

- KNIME workflows analyzed measurement data from “limit sample” runs.

- Once results were available, the workflow sent optimal starting values back to the R2R system via an API.

- Outcome: By automatically centering subsequent production lots after limit sample runs, Qualcomm significantly shortened the sampling period for new products.

“We were actually able to limit the time span of customer sampling for new products tremendously because production lots following these limit sample lots are already centered.” Dr. Jennifer Linden, Team lead DA Smart Factory

Results: Data-Driven Automation at Scale

After finalizing the multi-site rollout, Qualcomm quickly saw benefits in both day-to-day operations and new product development:

- 35+ deployed use cases in the first year, all developed and deployed by domain experts. These workflows ranged from adjusting tool settings to inserting or removing process steps as needed.

- Mindset Shift: Qualcomm embraced the idea that process engineers, rather than IT experts alone, could design and implement critical automation steps. Engineers now drive automation without IT bottlenecks.

“KNIME acts here as a microservice, so all those old school strategies… they’re still applying here. We’re still modular, we’re still connecting everything.” Thomas Pietras, Team Lead Production Data Analytics

Looking Ahead

After seeing success in Munich and Singapore, Qualcomm is now extending KNIME’s capabilities beyond its initial power users. The company plans to expand KNIME access to a broader base of employees, creating an internal community of practice.

Learn more about KNIME Business Hub and how it can help your organization or schedule a demo with our customer care team to see how it works in practice.